by products and services.

In order to create a lot of products and services that contribute to a sustainable environment, we have established an evaluation system for environmentally friendly products. The system is used for the purpose of promoting communication by disseminating information internally and externally, or by applying for internal environmental contribution awards as well as the awarding development divisions of the certified models under the evaluation system.

There are some evaluation points in products such as electric power consumption reduction, smaller size and weight, reduced number of materials and parts, longer product life, and promoting plastic free. And the following evaluation points at each stage of the product life cycle are used as evaluation criteria, such as reduction of power and water consumption in the manufacturing process and reduction of packaging volume during transportation.

Super Advanced Eco-Model

Products with outstanding environmental performance

Products with industry-leading environmental performance or products incorporating Pioneer's original environmental technologies. The Environment executive officer certifies it.

Representative example model: NP1

Advanced Eco-Model

Products with superior environmental performance

Products with superior environmental performance Products with environmental performance of a certain level, such as products with higher environmental performance than previous products. The environmental management department at the head office makes judgement the model adapts to the level.

Representative example model: Cyber-Navi (AVIC-CZ902), Raku-Navi (AVIC-RZ720)

Eco-Model

Products with basic environmental performance

Models subject to this level: All products

We are offering ŌĆ£Piomatix for GreenŌĆØ and ŌĆ£Piomatix LBSŌĆØ. The Piomatix for Green is a platform that provides solutions to environmental issues by combining our route searching technologies and our proprietary technologies for estimating fuel efficiency and electricity consumption rates. The Piomatix LBS is a platform that can be used for various systems such as cloud-based navigation and fleet management for EVs, utilizing a vast amount of driving history data and our patented routing technology. These platforms contribute to the reduction of CO2 emissions and other environmental burdens during driving in consideration with various conditions, such as drivers and traffic, in real time.

We have our years of wealth of knowledge and experiences in sound and manufacturing of in-vehicle equipment. Based on them, we have developed lightweight speakers that are environmentally friendly without compromising the quality of in-vehicle sound. We are contributing to the reduction of GHG emissions in the supply chain through reducing the size and weight of the product as well as the amount of materials used by not only reducing the weight of the component parts, but also by utilizing the structure of the vehicle as part of the speaker structure.

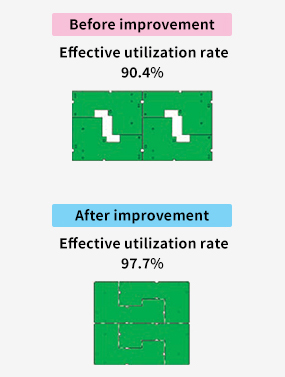

Our products use printed circuit boards (hereinafter ŌĆ£circuit boardsŌĆØ) on which electrical components are mounted. The circuit boards are cut and mounted onto products in the production line, and the excess portions are recycled as material. Focusing on the reduction of the recycling portion, we define an indicator called ŌĆ£effective utilization rateŌĆØ (calculated by dividing the used area by the total area), set a target, and manage it in product development. We also optimized the shape of our circuit boards against the ones supplied from manufacturers. As a result, substrate manufacturers are able to use raw materials more efficiently and reduce their waste and CO2 emissions in manufacturing and transportation.

Moreover, for us it is led to reducing the recycling portion on circuit board, raising awareness on wastefulness, and accelerating cost reduction. It has a positive effect on reducing the environmental impact on the supply chain.

We have worked on reducing the magnet cover (plastic protector) on the back of the speaker unit as the activity of reducing the number of consisted parts onto the product. This was achieved by focusing on parts that are almost invisible to the customer and that do not affect performance. The reduction in the number of parts contributes to environmental conservation by saving resources. This is an example of an improvement activity that resulted from discussions across divisions such as between the department of exterior design and the department of engineering design during the product development process.