and promote recycling of the resources.

Pioneer aims not to input unnecessary materials but to utilize the input materials without ruined then ship products. With this concoct, Pioneer includes wastes (unnecessary materials) and valuables (materials having market values as resources) generated during business activities into assessment index to proceed the activities.

At the Recycle Center in Kawagoe Plant, we collaborate with business partner to recycle the stretch film for package, which is discharged in this plant into plastic bags, then reuse as trash bags. By recycling 531 kg of the waste film material in the fiscal year ended March 31, 2024, resources were saved, and 1,760 kg of the CO2 emission could be reduced. These recycled plastic bags are used not only at the Kawagoe Plant, but also at other Offices, including our headquarter and Myogadani Office.

Stretch film for package of parts and products is recycled to plastic bags

In the employee cafeteria of Kawagoe plant, we have been devised to reduce the leftover foods. The generated food wastes despite all efforts have been thermally recycled before. However, we have contracted with a new company that creates renewable energy from food waste to generate renewable electricity from biogas by methane fermentation of food waste. The generated residue is recycled as roadbed material, etc., helping to reduce the amount of final disposal.

Process from food waste to renewable energy

Food wastes

from cafeteria

Methane fermentation

Biogas

Power generation

Electricity

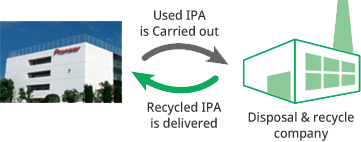

We changed handling method of the "IPA (isopropyl alcohol)" used for cleaning of the production machines from disposing to recycling after use. Moreover, we can carry out the waste liquid when carrying in the recycled solution, resulting energy for transportation can be saved and CO2 can be reduced.

Recycling Isopropyl Alcohol (IPA)

During development, prototypes evaluated for performance are disassembled and disposed of at a recycling center of Kawagoe plant. We exchanged related information with a recycling company and set a decomposition level that makes recycling easy. And the display of valuable prices by type of IC, circuit, material, etc. at waste collection area helps raise employee awareness of recycling.

Recycling center

Numbers are assigned to respective workplaces and indicated in all garbage bags to enable identification and feedback to the concerned division if there is any classification mistake. The items in which mistakes were made are posted on our internal portal site for all employees, and listed as the “Top 10 mistakes examples".

At the parts procurement stage, we select materials that enable reducing the number of types of plastic materials used, not adhering to different types of plastic materials, not attaching resin film to packaging boxes, and promoting use of recycled materials. We select materials which are easily collected, classified, and dismantled.

Considering collection,

classification,

and dismantling

At the design stage, product assessments are conducted for the following items, and target values are set for each item to promote product development with an emphasis on resource recycling.